- 20% Labor savings

- 200% increase in order volume with your current staff

- 50% reduction in data entry

- 100% reduction in paper

- 4-to-6-month ROI payback!

WithoutWire has modernized the mobile interface for warehouse, production and field technicians. With real-time integration to Dynamics, our solution needs minimal training to gain maximum adoption among your workforces. Contextual intelligence guides workers to follow a process that is predictable and repeatable. With our focus on simplifying complex inventory challenges we have introduced a powerful mobile experience for replenishing inventory with a Just-in-Time (JIT) supply just when you need it, at just the right quantities.

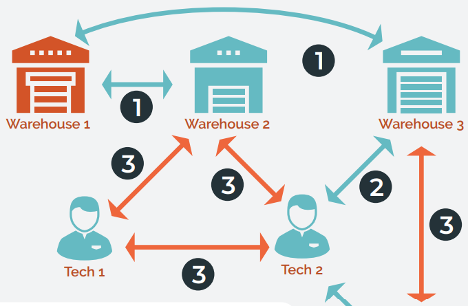

Field technicians are a valuable resource for completing those tough service tickets, performing installations against work orders and executing on maintenance and repair jobs. When the tech does not have the right parts, or not enough parts, they are faced with multiple trips to close their work order and/or they become engulfed in supply chain challenges … which is not what they were paid to do.

Through WithoutWire enhanced replenishment, JIT supply is automated through the easiest mobile experience on the market today. Request inventory required for upcoming jobs through mobile and have them automatically shipped to your driveway or an unmanned facility for pick-up. No paperwork, no data entry, and the most efficient use of your skilled workforce.

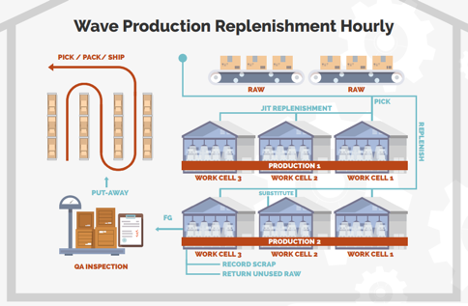

If only we had unlimited space in our warehouse. Particularly in manufacturing staging. Production jobs often span a whole or multiple shifts throughout the day. Shutting down the line to wait for raw material delivery creates tremendous inefficiency. WithoutWire has constructed the replenishment logic to schedule raw material deliveries JIT. Fully automated through mobile we take the complexity out of your required production inventory supplies. Just set it. And forget it. We can drive an hourly re-supply via our automated mobile WithoutWire software. Production runners follow the pick tasks and replenishments driven by our mobile application. No more production shutdowns. No more interruptions in each shift. No more overflow of materials in staging.

By automating the mundane replenishment tasks your production team can focus on accurately recording the raw material and finished good lots, expiration dates, recording scrap, returning unused raw materials and the proper quality inspection!

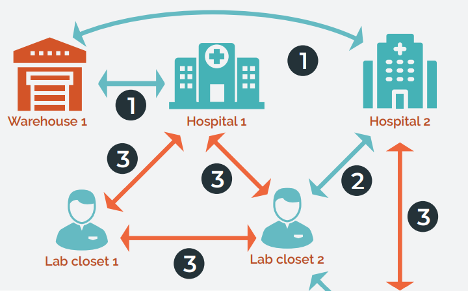

Laboratory and medical supplies are examples of where stock-outs can literally be a case of life or death. Who says supply chain is not important? Nurses and lab technicians should never run out of critical hospital and medical supplies to do their job. Gloves, masks, syringes can be critical to their protection and the protection of their patients. Through WithoutWire enhanced replenishment, lab closets and hospital supply rooms never run out of those critical supplies. Cross-site replenishment was a challenge that WithoutWire had to simplify and solve for our clients. Transfer picks, in-transit and cross-site moves all follow one set of logic within our system. Simple, consistent and predictable flow of goods throughout and beyond the 4 walls of your warehouse!

WithoutWire has extended its solution to the Microsoft Power Platform using low-code, no-code power connectors.

https://docs.microsoft.com/en-us/connectors/withoutwireinventory/

Now Microsoft partners and customers are empowered to complete their solution using the WithoutWire Inventory Platform of low/no code connectors.

We hope to collaborate with you soon to solve your complex inventory challenges … just in time!

Steve Dwyer, Chief Revenue Officer

WithoutWire

612-839-4058

steved@WithoutWire.com